Projects

Exterior Jet Bridge Coating Reduces Energy, Increases Passenger Comfort in Las Vegas

Author: Kristen Rindfleisch – Airport ImprovementPublished: October, 2023 Harry Reid International (LAS) in Las Vegas regularly sees temperatures of more than 100 degrees Fahrenheit (37°C) throughout the summer, requiring significant energy to cool its passenger boarding bridges. The Clark County Department of Aviation, which operates LAS, has opted to have a reflective ceramic coating applied to bridge … More

Baku Metro Underground Tunnel Corrosion Protection

The client was seeking a coating system which was both surface tolerant and fast drying. The underground metro system was cast iron steel, which could not be shutdown or abrasive blasted since it was in operation 365 days a year. After extensive testing by head of Baku Metropolitan Tunnel Authority, Rust Grip® was sole specified … More

City of Adelaide Cool Roof Trial 2022-2023

Bitumen roads and building materials collectively absorb and store the sun’s solar heat that contributes to excessive heat in our cities like Adelaide and dense urban areas which is known as the urban heat island effect. These heat islands are significantly hotter than temperatures in surrounding suburbs and rural areas and impacts the well being … More

Abu Dhabi LNG Super Tanker with Rust Grip®

Marine Environment in Abu Dhabi LNG Tanker The client ADNATCO is owned by Abu Dhabi National Oil Company (ADNOC’s) marine transportation company for crude and gas shipments, primarily sent to Asia. The application took place in Dubai Dry Docks on two separate vessels, on the Monkey Islands. The parent company ADNOC conducted detailed laboratory testing … More

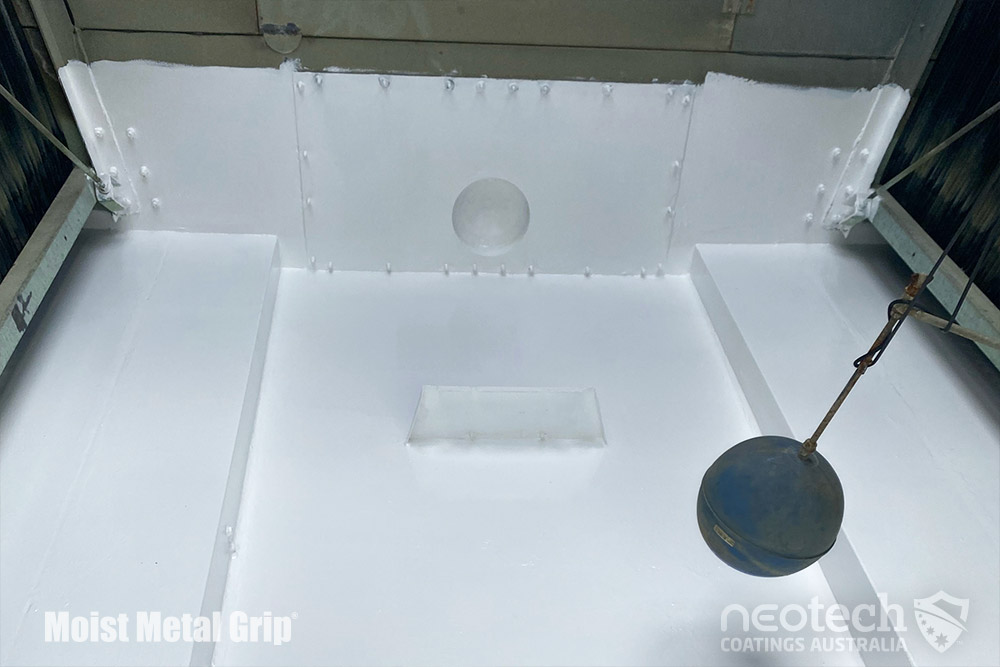

Water cooling tower corrosion treated with Moist Metal Grip

NEOtech Coatings were approached by Coolblue Airconditioning in Yallah, New South Wales who were looking for a solution to corrosion in a water cooling tower’s air-conditioning system. The cost of maintenance to remove the tower with a new structure was prohibitive for the client’s budget and Moist Metal Grip® was introduced as the best solution … More

Poland Pantech with Super Therm Ceramic Coating

19% of energy reduction and an average 4°C – 7°C lower temperature Goal of the test: Showing energy savings possible to gain after application of Super Therm® coating on the roof of refrigeration truck. Full Report pdf Procedure of the test: Conducted test relied on comparison of cooling down loading space of two identical refrigeration … More

World’s Largest Blue Chip Casino Boat Build

The three-story Blue Chip Casino located in Michigan City, Indiana, is the largest US Coast Guard approved casino vessel ever built in USA at a cost of construction was budgeted at $163 million. Managed by and certified all coating application by John Grey and Steve (Superior Products, Inc.) for Superior Products International II, Inc. Just … More

Moist Metal Grip antifouling paint on an Australian houseboat

Project Problem Peter Davey is based in Nelson Bay, NSW and has been boating for over 40 years. Every year he would undertake the laborious task of taking his boats out to dry dock to clean the hull, remove the biofoul using plastic drop sheets to capture the waste for the environment regulations and then … More

Chevron Pacific Gas Pipelines, Indonesia

Project Problem Chevron Pacific Indonesia, PT faced various problems at one of their gas pipeline locations in Indonesia. Because of condensation and lack of maintenance, the gas pipeline was affected by severe corrosion problems. They could not stop operation of the pipelines for maintenance, and the repairs had to be completed while the pipelines were … More

Chevron Pacific Oil and Gas Refinery, Indonesia

Project Problem Chevron Pacific Indonesia, PT faced various problems at one of their oil and gas refinery locations in Indonesia. Because of high temperatures, high humidity, and lack of consistent maintenance, most of the pipelines and storage tanks were affected by severe corrosion problems. The location needed to be in operation for at least 10 … More